Since its inception in 1990, ILG (International Logistics Group Ltd) has become a market leader in fulfilment and courier services. During this time it has evolved alongside the e-commerce sector and major developments in the courier and freight industries.

ILG currently operate out of four sites in Crawley, Burgess Hill, London (SE1) and the newest site in Gatwick which opened in June 2015 specifically as an e-commerce fulfilment centre to service their clients in the demanding fashion and beauty sector.

The original layout of the facility was logical and effective to meet the immediate needs of the clients however ILG wanted to ensure that they could increase the volume of customer product orders through the facility to meet their client’s substantial growth targets.

Without a specific strategy in place to optimise layouts (including better use of the facility height) and workflows there was the potential that a rapid and large increase in volumes could create significant bottlenecks, subsequently affecting efficiency and capacity output.

ILG instructed the Warehouse and Distribution Centre Specialists at The Supply Chain Consulting Group (SCCG) to carry out a detailed review of the site processes (including how e-commerce and wholesale orders are processed), layouts, workflows, equipment (as there was a mix of racked and floor based picking) and systems with a view to providing a strategy and recommendations for a fully optimised facility to meet current and future requirements.

| “We are really impressed with the excellent work done by the Warehouse Specialist from SCCG, the whole process was invaluable and will greatly assist us with our growth plans for this sector”. Tom Ashley – ILG – Operations and IT Director |

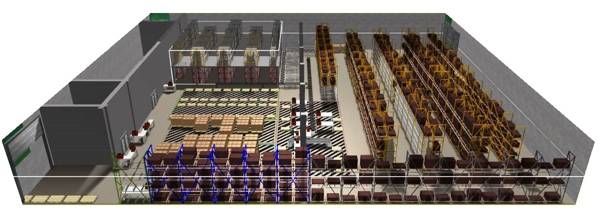

The SCCG consultants provided a revised operational layout designed to deliver the most efficient flow of products in and out of the building and introduced new SOPs (Standard Operating Procedures) to optimise the use of the new equipment, facility layouts and workflows

The improvements include extending the flow rack picking faces and introducing mobile flow racks for multi-purpose use across all customer products.

The packing operation has been centralised with new packing stations fed by conveyors from the pick face and using ‘check-out’ lanes.

The Bulk Picking area has been re-configured to ‘pick by line’ to increase pick efficiency and the inbound and outbound marshalling areas have been split into separate defined floor locations with a separate dedicated returns processing area.

The issue of optimising the use of building height was addressed by introducing a two storey Mezzanine storage & picking area. The facility also now benefits from an increase in pallet racking capacity and a dedicated Packaging materials storage area.

The issue of optimising the use of building height was addressed by introducing a two storey Mezzanine storage & picking area. The facility also now benefits from an increase in pallet racking capacity and a dedicated Packaging materials storage area.

All of the above has contributed to increased capacity, efficiency and longevity of the Gatwick Facility.