After 30 years in development, practical applications of 3D printing are now becoming commonplace and disrupting traditional businesses. Supply chains across diverse industries such as aerospace, healthcare and electronics are devising solutions to enable them to take advantage of market opportunities.

Doctors can print a model of a person’s heart before tackling invasive surgery and logistics companies can build drones to address delivery challenges. Printing of 3D guns – maybe not so good?

What is 3D printing?

Industrial style 3D printers inject materials in successive patterns to build a three-dimensional object. The term “additive manufacturing” is used to explain this principle. Various types of technologies are applied but they all have the same objective: to create complex designs and customizable products on an individual basis with less effort than traditional manufacturing processes.

3D technology is a supply chain disruptor

3D printing technology enables companies to design and produce new customised products to meet the end user’s growing needs for personalization. Consumers have become accustomed to being able to demand products with variations that were not previously available. The rise of e-commerce is compounding the need for retailers to be innovative and responsive. The extensive use of mobile devices is also feeding the need for instant gratification and same day deliveries.

In order to stay competitive in the online marketplace, companies are turning to 3D printing to create their products quicker. The analyst firm Canalys anticipates that the worldwide market for 3D printers and its associated materials and services will grow to $20.2 billion by 2019.

The advances in 3D printing have been a game changer for manufacturers. Certain types of spare parts can be printed on demand. This means reduced lead times for their customers, lower inventory levels and cost savings in warehousing. Significant competitive advantage can be gained by speed-to-market.

Aerospace

GE Aviation has announced plans to manufacture 40,000 jet fuel nozzles by 2020. GE is also designing an advanced turboprop that replaces more than 850 parts of a normal aircraft engine with only 12 3D-printed components. Boeing and Airbus have both made significant investments in the technology. Airbus has unveiled a drone made of parts that have been 3D printed in polyamide.

Both GE and Airbus have found that the technology allows them to redesign aircraft parts to reduce their weight, saving costly fuel.

Automotive

Leading automotive manufacturers were the early adopters. Ford, Mercedes Benz and BMW are all continuing to look at how to improve service levels. Spare parts can be produced on demand nearer to the market they serve from designs that are sent electronically across the world.

Healthcare

The precision that comes with 3D technology is a boon for the medical professions. Custom-made prostheses can now be produced with less weight improving wearability. Models can be made of the human heart and its arteries to allow surgeons to preview conditions before embarking on invasive surgery.

Small and medium enterprises (SMEs) can also benefit. They have the freedom to buy local and save themselves the complications of importing, storing and transporting goods and the associated administrative headaches.

Impact on the logistics industry

As 3D printing technology develops and is used more widely, the logistics sector will be affected. As manufacturing processes are simplified, supply chains will be shorter and the demand for transport will change. It is projected that the volume of imports from Asia to Europe will drop considerably in the next few years.

Logistics companies such as DHL and UPS are already benefitting from on-demand printing by providing extended distribution facilities and partnering with 3D printing companies.

The main benefits of 3D printing

- Reduced production times

- Lower inventory levels and less obsolete products

- Printing-on-demand using digital files

- Fewer suppliers through consolidating purchases

- Local supply means cheaper transport and easier logistics.

- Increased Responsiveness

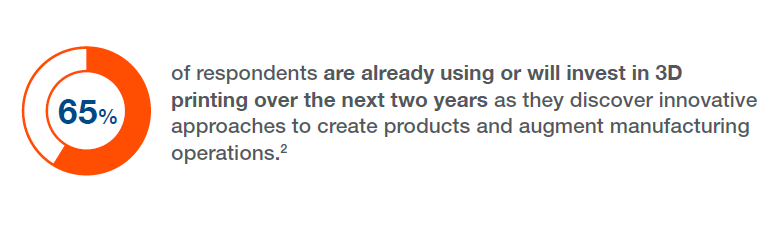

According to a recent Gartner survey….

The rise and rise of 3D printing

Industrial-grade 3D printers cost upwards of US $1 million. The challenge in the longer term is to improve the technology and make the printers faster, cheaper and more agile. They need to be able to use different raw materials and be capable of producing higher-quality items. Increased accessibility to hardware, software and new raw materials is already driving down the cost of 3D printers.